First of all, let me introduce a concept, what is the package technology of liquid crystal display? Whether it is a mobile phone, a monitor, or a handheld device, their screen is not just a piece of liquid crystal glass. In order to "light up" the screen, it is necessary to connect the LCD panel to the display driver IC and FPC(flex panel connector) cable. The driver IC mainly controls the voltage of the liquid crystal layer to control the brightness of each pixel. The FPC is the connection carrier between the display module and the main board of the device. The packaging technology we talk about is how to realize the interconnection of the LCD panel, the driver IC, and the FPC cable to light up the LCD screen. The development of packaging technology is very rapid, COB, COG, COF, COP and other packaging technologies. However, COF and COP are mostly used in the smartphone market because of their screen-to-body ratio advantages. In the traditional industrial display field, COG technology isstill the mainstream.

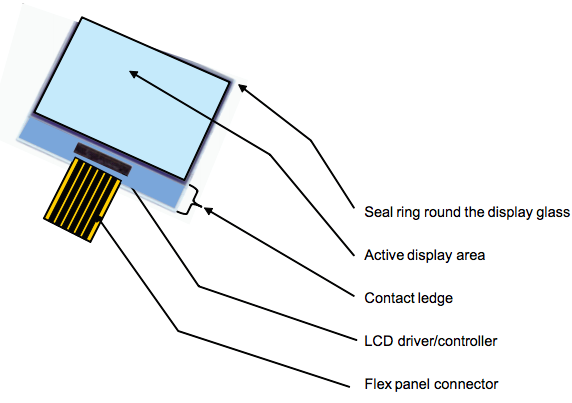

COG the full named chip-on-glass. As the name suggests, it is chip technology on glass. Realize that the driver IC conducts electricity and is interconnected and packaged with the conductive pad on the liquid crystal glass, so as to realize the lighting of the screen.

For designers of industrial displays, automotive displays, and portable devices, LCD screens with COG packaging technology have

many advantages over traditional packaging.

The liquid crystal display is usually presented in the form of a liquid crystal display module, and its built-in driving circuit is easy to install and has high reliability. However, adding a traditionally packaged drive circuit to the LCD module will also lead to some disadvantages, such as:

1. Increased the thickness of the display.

2. Increased cost.

3. Increased the failure rate of LCD module.

All of these drawbacks are important considerations when it comes to displays for industrial, automotive and portable devices. This is why designers in these fields should strongly consider LCD modules using COG. Those modules has a very thin profile, high reliability, and reasonable cost price.

The concept of COG

The COG display module installs the driver IC directly on the edge of the liquid crystal glass, with a thickness of less than 3 mm, and all connections from the driver IC to the LCD module are completely isolated from the environment. With COG, only one bond is required per driver IC connector, which ensures optimum reliability of the module.

Another benefit of COG technology is that it supports a wide variety of design options with virtually no limitations. The location of the driver IC can be placed on any side of the liquid crystal display area. This allows optimal use of the available space around the display (e.g. to mount switches).

Any type of liquid crystal technology can be used:

TN display technology: LCD screens using twisted Nematic (TN) technology produce black pixels and characters against a clear background.

STN display technology: Super twisted Nematic (STN) technology is used for display screens that require high multiplexing rates. This technology provides a high-contrast display with wide viewing angles.

Summary

Designers in the field of industrial displays such as medical equipment, vehicle displays, and portable devices should focus on using LCD modules with COG to meet their display needs. COG display modules are thinner, more reliable, more flexible, and more cost-effective than traditional packaging liquid crystal display products.

Thanks for reading this article, next time we would like to bring you more knowledge of LCD.